Aerospace Sector

Date:2019-07-12Source:Views:

Carbon fiber is a fibrous carbon material that contains more than 90% carbon. Compared with other high performance fibers, it has the highest specific strength and specific modulus. Especially in the high temperature above 2000℃ inert environment, carbon fiber is the only material which does not decline in strength.

In addition, it also has a variety of other unique performance: low density, high rising heat, high temperature resistance, corrosion resistance, friction resistance, anti-fatigue, high vibration attenuation, low thermal expansion coefficient, conductive and thermal conductivity, electromagnetic shielding. Therefore, carbon fiber composites also have excellent properties to be applied in the field of aerospace.

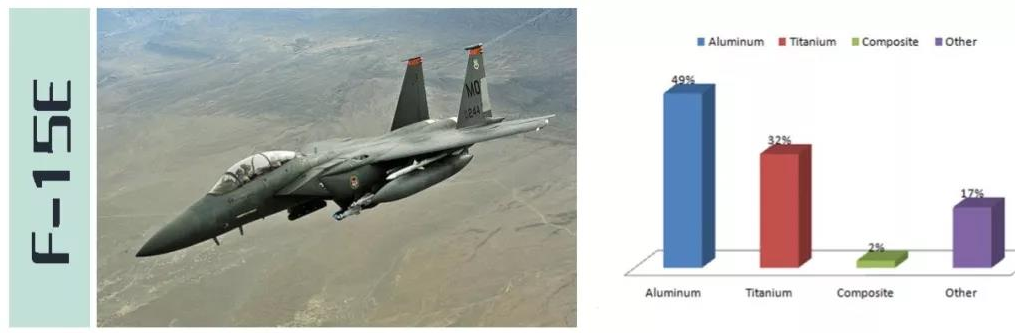

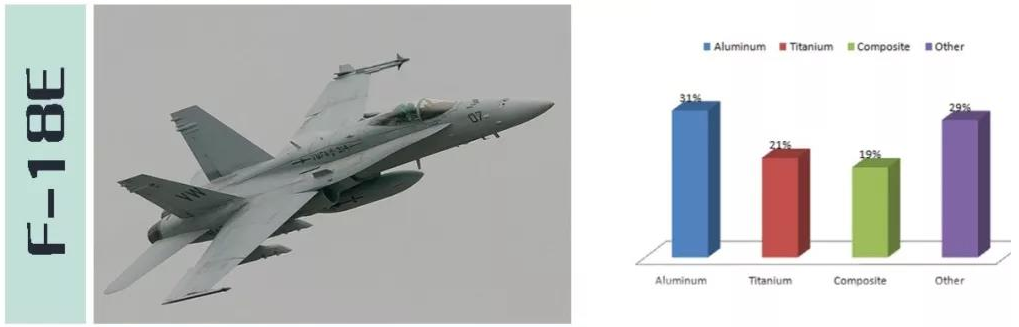

Carbon fiber reinforced resin matrix composites (CFRP) are important materials for weapons production. In fighter aircraft and helicopters, carbon fiber composites are used in the main structure, secondary structure parts and special functional parts. It will reduce a lot of weight and greatly improve the fatigue and corrosion resistance. Data showed that the forward fuselage section which used carbon composites structure, comparable quality of metal structure to reduce by 31.5%, reduce 61.5% spare parts, fasteners 61.3%. The composite vertical stabilizer can reduce the mass by 32.24%.

It’s learned that the fourth-generation US fighter jet F-22 is made of about 24 % carbon fiber composite, giving it ultra-fast cruise, over-the-horizon operations, high mobility and stealth. And one of the reason that F-35's first flight time has been delayed again and again is overweight.

To solve the problem, they used 35% carbon fiber composites to significantly reduce body weight. "Only composites have the potential to deliver 20-25% performance gains by 2020," the department of defense emphasized.