Composite Material Layering Design

Date:2023-11-20Source:Views:

The most basic unit of composite materials is the layer. Layering is a unidirectional layer of composite materials formed by a layer of unidirectional tape or fabric in composite materials. A composite material board made by laminating and pressing two or more layers of the same or different materials is called a laminated board. The basic unit of composite laminated structural components is precisely this type of laminated plate composed of various layer design elements.

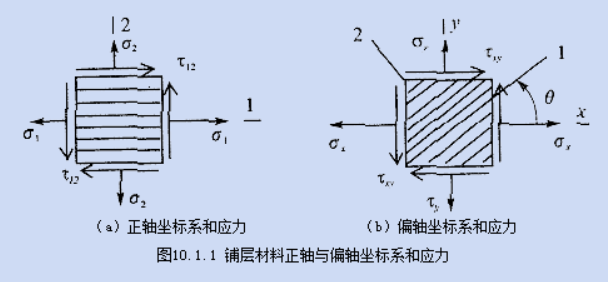

Layering is the basic structural unit of laminated boards, with a very thin thickness, usually around 0.1-0.3mm. The direction of the reinforcing fibers in the layer or the radial fiber direction of the fabric is the main direction of the material (1 direction: i.e. longitudinal); The direction perpendicular to the reinforcing fiber or the weft fiber direction of the fabric is the other main direction of the material (2 directions: i.e. transverse). The 1-2 coordinate system is the main coordinate system of the material, also known as the positive axis coordinate system, and the x-y coordinate system is the design reference coordinate system, as shown in following picture.

The laying layer has direction. The direction of the laying layer is determined by the fiber laying angle (laying angle) θ express. The so-called ply angle (ply angle) refers to the angle between the longitudinal direction of the ply and the reference coordinate X axis of the laminated board, which rotates counterclockwise from the X axis to the longitudinal direction of the fiber and becomes positive. If the reference coordinate system X-Y coincides with the main direction of the material, it is a positive axis coordinate system.