Basalt fiber new composite material can be used for the interior of railway carriages

Date:2024-10-17Source:Views:

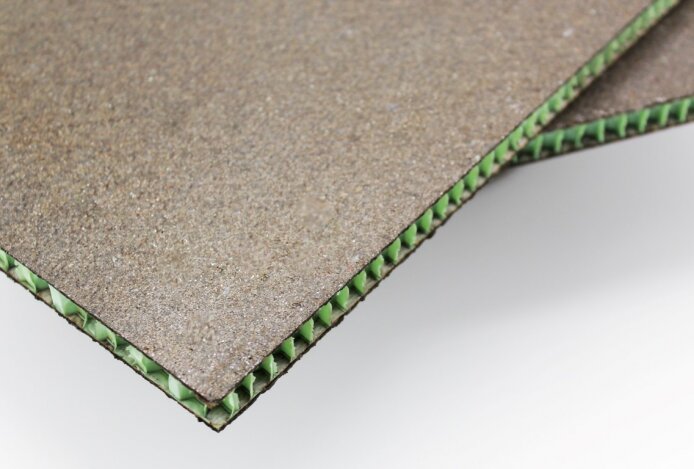

Basaltex, pioneers in innovative uses of basalt fibres, has achieved a significant milestone in developing and testing a new composite material solution comprising fibres of basalt combined with EconCore’s patented honeycomb technology.

The development of this new material greatly improves its fire resistance and has high rigidity and honeycomb lightweight characteristics. The company has tested composite materials of basalt fiber, bio resin, and rPET honeycomb. Long filaments made solely from stone fibers are extruded at 14500 degrees Celsius, similar to glass, but without the presence of boric acid during the process.

The addition of bio resin polyfurfuryl alcohol (100% from sugarcane waste) to the new basalt fiber composite material makes it a sustainable and environmentally friendly product. Compared to the widely used traditional integral fiberglass inside trains, it will significantly reduce its weight.

This sandwich panel can be applied to cladding panels, partition walls, tables, and floors. The thermosetting surface can cure quickly at high temperatures, which means that the cycle time is short and automated production can be achieved. Like internal railway applications, this new material combination can be used in any market that requires fire resistance and lightweight design.