Low cost and efficient CFRP anisotropic mesh structure

Date:2025-01-08Source:Views:

The anisotropic mesh carbon fiber reinforced polymer (CFRP) mesh shell is one of the most effective designs for reducing the weight of spacecraft heavy-duty structures. They are composed of regular patterns of intersecting circular and spiral ribs (with or without thin outer skin), providing in-plane (membrane) and out of plane (bending) stiffness, which is crucial for preventing buckling under high compression loads.

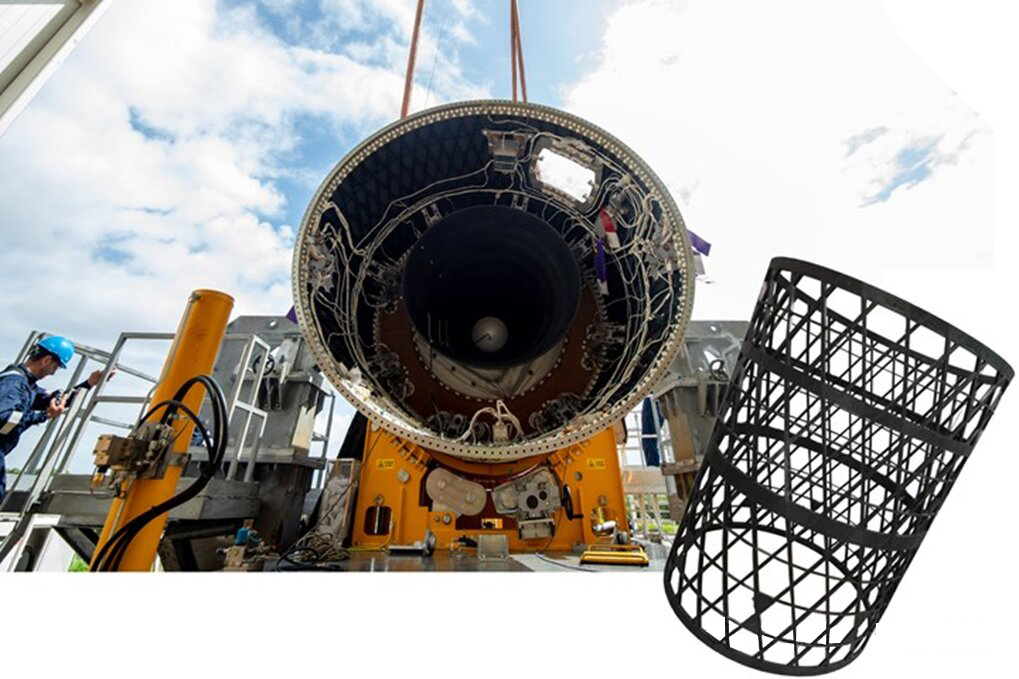

In the past two decades, the Italian Aerospace Research Center (CIRA, Capua, Italy) has improved the design and manufacturing of its CFRP mesh structure through prepreg and wet winding, as well as improved design analysis. By 2009, it had obtained a patent for the "parallel winding" technology, which first uses dry fibers and then injects resin. The result is an interwoven anisotropic grid with uncut continuous filaments and no false spiral patterns. The process developed by CIRA is clean, efficient, and scalable, capable of producing ribs ranging from very thin to very thick (with a cross-sectional area of 4-400 square millimeters). Avio (Colleferro, Italy) has used this process to produce the 2/3 stage of the Vega-C space launch vehicle, which made its first flight in 2022. Subsequently, CIRA further demonstrated the scalability of the method, producing large central tubes and long instrument arms for satellites, as well as conical payload adapters for launchers.