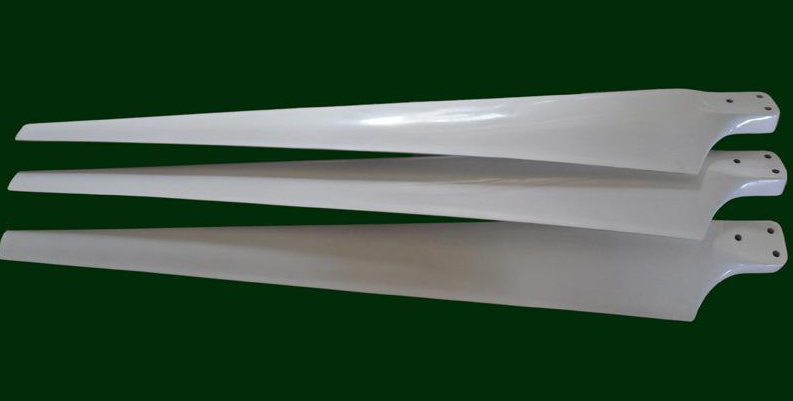

Fan Blade Sector

Date:2019-06-03Source:Views:

With the development of the world economy, wind energy as a renewable energy has attracted more attention all over the world. Wind turbine blades are important equipment for wind power generation. With the progress of science and technology, the size and weight of wind turbine blades are getting larger and larger, and the material has changed a lot. Carbon fiber composites are applied in the blade design now.

The traditional blades are mostly made of glass fiber, which is relatively heavy and has many shortcomings in performance compared with composite materials. Under the action of extreme wind load, the blade tip should not touch the tower. The blade must have strong rigidity and should not be reduced when reducing the weight. Carbon fiber composite material can meet the high power demand of wind power generation devices. It breaks through the performance limit of glass fiber composite material, and can help the wind power blades greatly reduce the weight while increasing the length.

Advantages of carbon fiber composites in wind turbine blades

● Improve rigidity, reduce weight

The specific strength of CFRP is about 2 times than GFRP, and the specific modulus is about 3 times. For wind turbine blades of the same power set, the use of carbon fiber can significantly reduce the weight of the blades.

● Make the output power smoother and more balanced, improve the utilization efficiency

Because of the use of carbon fiber, the reduction of blade weight and the increase of rigidity improve the aerodynamic performance of the blade and reduce the load on the tower and hub. At the same time, carbon fiber allows the blades to be designed thinner and more efficient. Longer blades will increase the efficiency of energy output. In addition, the use of CFRP in large flexible wind turbine blade structures, such as the girder cap and the skin, can realize the bending-torsion coupling design of the blade and optimize the efficiency output while reducing the fatigue load of the blade.

● Improve the adaptability of blades to harsh environment

Wind turbines work in harsh natural conditions for a long time. Factors such as humidity, fatigue, storm and lightning strike may make wind turbines vulnerable to damage. CFRP not only has high compressive strength and excellent fatigue resistance, but also has good corrosion resistance to acid, alkali and salt.

● Reduce the manufacturing and transportation costs

When the blades exceed a certain size, CFRP blades are cheaper than GFRP blades because the material usage, labor, transportation, and installation costs all decrease.

Application prospects of carbon fiber in the wind power industry

In the future, carbon fiber will be increasingly used in wind power industry, especially in the field of offshore wind power. The rated power of the offshore wind turbine will exceed 20MW and the rotor diameter will be about 200m. The carbon fiber can provide lighter, more tensile and corrosion resistant blades and tower materials for offshore wind power generation.

The use of carbon fiber will make the wind turbine to the light, large-scale development. The overall power efficiency will be improved. The future of carbon fiber in the large-scale popularization and application in the field of wind power and wind power market gradually mature to wind turbine manufacturers benign competition, ongoing technological innovation, promote carbon fiber composite material molding technology development to the direction of low cost.