New Path for Energy Conservation and Emission Reduction

Date:2024-03-21Source:Views:

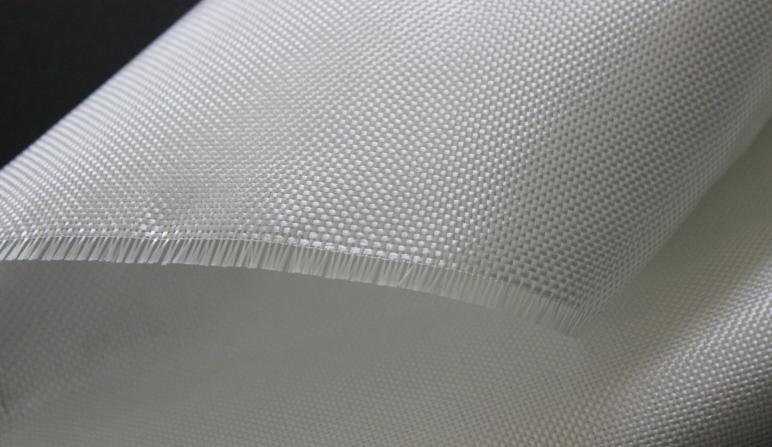

In recent years, Shandong Fiberglass has vigorously promoted Digital transformation, built several digital fiberglass production lines, won honorary titles such as "national green factory", "provincial high-tech enterprise", and was selected as one of the top 50 leading enterprises of new materials in Shandong Province.

It is worth mentioning that the company actively explores new paths for energy conservation and emission reduction. Taking the company's annual production of 60000 tons of ECER fiberglass production line as an example, in the past three years, various technological improvements have been made, such as the utilization of waste heat from steam condensate in drying furnaces, the conversion of ozone denitrification in waste gas treatment stations to SCR denitrification, and the adjustment of electrode clamps to reduce power consumption through leakage plates, effectively achieving energy conservation, emission reduction, and efficiency enhancement.

In the future, the company will also adopt automatic unloading, AGV automated logistics, three-dimensional warehouse, and robot packaging technology for this project to improve labor efficiency; In winter, hot air from some kiln workshops is extracted as air conditioning return air, and the return water from circulating water is used as a heat source for wire drawing air conditioning, in order to reduce the cost of air conditioning operation and achieve energy-saving and consumption reducing effects.